Pharmaceutical & Medical Solutions

At Excel, we believe that the work we do makes a meaningful impact. Our commitment to assisting clients in reaching their goals of discovering, developing, and producing lifesaving products fills us with immense pride. Over the years, our work in the pharmaceutical industry has led to the development of high-quality fabrication techniques that meet and exceed our customers’ requirements and expectations. Excel has extensive experience in designing, fabricating, and installing a wide array of systems for all applications in the pharmaceutical and medical sectors. Our involvement in the industry is divided into two main branches: Process Equipment and Distribution Piping.

Process Equipment

Excel has been providing the Canadian pharmaceutical industry with reliable TSSA-approved process equipment (skids) for over 30 years. Our success in this sector is partly due to our experienced team, which reliably designs and documents each project to meet customer specifications and requirements. Utilizing the latest CAD software, Excel creates custom pharmaceutical skids that include framework, piping, electrical systems, and system controls. Before fabrication, all materials and components are pre-inspected and documented to ensure full traceability and compliance with industry standards.Excel’s skids are prefabricated and pre-assembled in our shop, with passivation and factory acceptance tests completed prior to shipment. Once finished, our field installation team delivers and installs the prefabricated interconnecting piping between the skid and any required utilities, providing a turnkey solution.

Distribution Piping

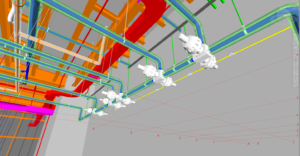

Excel is at the forefront of pharmaceutical process piping layout design and field installation in North America. With extensive experience in large-scale projects involving over 17 miles of stainless piping, our team excels in installing documented and traceable systems for purified water, water for injection, clean steam, clean compressed air, clean-in-place systems, product piping, and all necessary process drainage piping.Excel’s affiliation with the CANBIM association allows us to leverage the latest software technologies to provide flexible solutions to complex problems in collaboration with other trades. Our engineering team can also provide real-time CAD representation of our field installation progress with remarkable accuracy down to 0.0625 inches.

Prefabricated and passivated in-house, Excel’s approach optimizes scheduling, minimizes field installation downtime, and maximizes productivity. With orbital welding capabilities ranging from 1/8” to 6”, Excel can meet all requirements for the pharmaceutical industry.

Industrial Process Piping

Excel excels in the realm of process piping, distinguishing ourselves from the competition. Our engineering team is adept at designing highly complex systems, regardless of their length. Paired with our expert fabrication and field installation teams, we ensure consistent, timely solutions for the entire project duration, no matter the size. Our experienced operations team upholds the highest standards of craftsmanship. The quality of workmanship we have consistently delivered to the pharmaceutical industry has earned us a reputation for excellence that our competitors cannot match. With over 30 years of refinement, our quality remains unparalleled.

We cooperate with

Water Treatment

At Excel, we are committed to safeguarding Canada’s fresh water for all industrial uses. The energy sector, in particular, utilizes large volumes of our freshwater and requires intricate, complex piping systems to ensure their safe and environmentally friendly return to the environment. Excel has supplied prefabricated piping systems to numerous water treatment facilities across the Canadian energy sector. Trusted by these corporations to deliver reliable systems, we have consistently met their needs with excellence and dependability.

Automotive

Whether you are a car enthusiast or simply use a car for your daily commute, you likely expect a long-lasting, rust-resistant paint job. Our clients do too. That’s why major players in the Canadian automotive industry, including the big three as well as Honda and Toyota, rely on Excel for upgrading and maintaining their paint shops. These facilities produce iconic models like the Civic, Corolla, and Challenger, among others. Our expertise extends beyond OEM final assembly to automotive supplier and feeder plants requiring fabricated paint, solvent, and gas piping. Whether our systems are in a Tier 3 or Tier 1 supplier facility, or at Ford or Chrysler assembly plants, their consistent quality and performance in demanding environments are a testament to our engineering and craftsmanship.

Food and Beverage

Strengthening local industries by supporting the automation of high-frequency production lines is a core expertise of our team. Excel’s piping systems are integral to modernized production lines in bottling, chocolate, cookie, and candy production plants. Clients throughout the food and beverage industry consistently return to us, thanks to our unmatched quality and timely deliveries, ensuring the success of their automation and process improvement projects.